EMERGENCY MANUFACTURING

Technique, Inc. can offer extremely rapid solutions to a number of production issues. We work around the clock, 7 days a week to solve problems to avoid downtime or line shutdown situations.

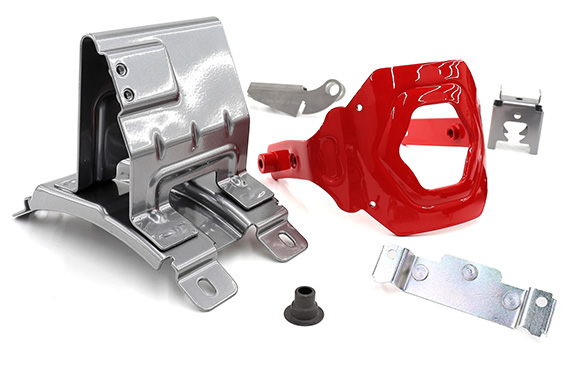

- We can complete any type of metal stamping, bent tubing, laser cut tubing or assembly.

- We have a jet airplane available for direct emergency shipments as needed

- We can produce quantities as needed — from a few dozen to 10,000+

- We utilize all tools at our disposal to be able to respond immediately to emergency situations:

- Laser cutting — flat and five-axis

- Short run or temporary tooling designed and built with an in-house tooling department

- Our technicians are highly-skilled, extremely experienced and are accustomed bringing complex parts on-line quickly

- Large inventory of in-stock materials for tools and parts

- We utilize computer simulations for tool design to reduce guesswork and lead times — saving you time and money

PRE-PRODUCTION

- In situations where a production tool isn’t available in time for start-of-production, we can create a fast, temporary tool to quickly manufacture and ship parts

- We meet PPAP and other production quality requirements as needed

TOOLING PROBLEMS

- In situations where a current production tool goes down or needs repair, we can fill the gap created with minimal tooling and downtime.

LATE CHANGES TO PARTS

- We can modify current production parts when there are production problems

- Whether you require trim line changes or changes to the form of the part requiring fast, temporary tooling, we can quickly make tools or utilize five-axis laser cutting to turn current parts into a new revision level

Looking to have a prototype built of your idea?

Have Technique call you now and discuss how we can help!